Can laser cut bone

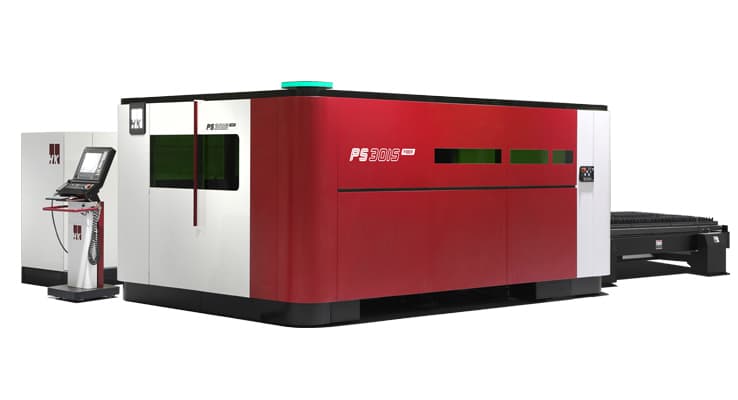

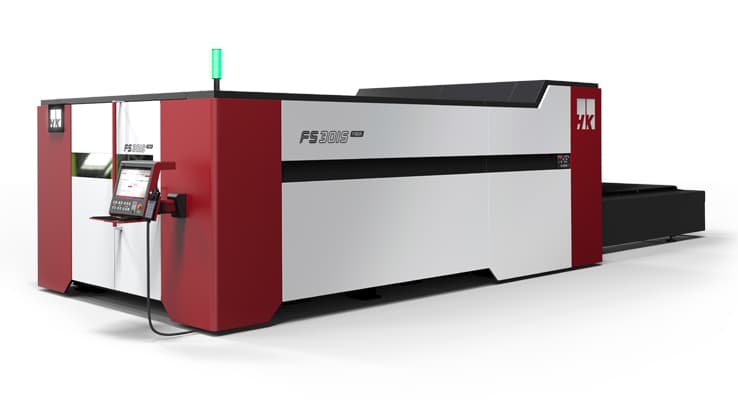

Need high-quality cuts? Need to get a handle on your operating costs? Fiber laser technology is a versatile, efficient, easy-to-use option that knows how to keep up with your needs.

Plasma on the other hand can effectively cut any kind of metal up to 80mm thick or 3 inches. Interestingly, plasma can start cutting faster than laser when cutting thicker materials.